All installed height safety systems require regular scheduled periodic inspection in accordance with the AS/NZS 1891.4.2009 Standard and manufacturers instruction.

Extract from AS/NZS 1891.4.2009, Section 9: Inspection, Maintenance and Storage: 9.1. Summary of Inspection Frequencies;

| Items |

Reference |

Inspection Frequency |

| Anchorages – drilled-in type or attached to timber frame |

Clause 9.3.3. |

12-monthly inspection by a height safety equipment inspector. (Note 1) |

| Anchorages - other types |

Clause 9.3.3. |

Frequency of inspection by a height safety equipment inspector as recommended by the manufacturer. 12-monthly inspection in the absence of such recommendation (Note 1) |

Note 1: Where used in harsh conditions, more frequent inspections may be required.

Manufacturer’s Recommendation

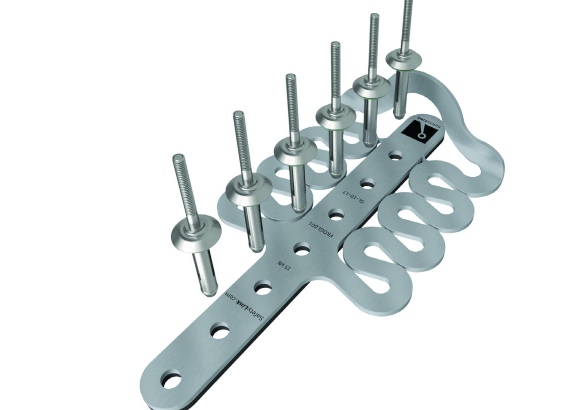

SafetyLink, the manufacture of FrogLink Anchor Points, recommend 12-montly inspection once installed. Anchors installed in harsh conditions, e.g. in wet, dusty, abrasive, or corrosive environments, (near the ocean for example), shall; be inspected more frequently at twice the frequency (6-monthly).

What is included in an anchor recertification/inspection?

Anchorages shall be visually inspected for signs of deterioration which might make them unserviceable, together with any other requirements contained in the manufacturer’s instructions.

The parent structure shall also be visually inspected for modifications or deterioration which might lead to loss of anchorage strength.

Frilled-in anchorages such as friction or glued-in anchorages shall be proof testing in accordance with AS/NZS 1891.4:2009 – Industrial Fall-Arrest Systems and Devices, Section 3 Anchorages, Clause 3.1.2(g) as part of each inspection.

What happens if an anchor fails an inspection or doesn’t gain a recertification?

In accordance with the Standards (AS/NZS 1891.4:2009 – Industrial Fall-Arrest Systems and Devices), any anchor which has arrested a fall or shows defect shall be withdrawn from service immediately and a replacement obtained if necessary.

A label indicating the condition or defect will be attached to the anchor and system before it is inspected by a height safety inspector who will device whether the equipment is to be destroyed or repaired if necessary and returned to service. In the latter case, details of any repairs will be documentary and a copy given to the building owner or manager.

Reference: (AS/NZS 1891.4:2009 – Industrial Fall-Arrest Systems and Devices – Section 9, Clause 9.5.

ISO

ISO

ISO

ISO

ISO

ISO

SiteWise

SiteWise

Masterspec

Masterspec